Solar Panel Basics and Types Of Solar Panels Used In Flood Lights

There are two main types of solar panels – Solar Photovoltaic (PV) panels and solar thermal energy panels. First generates electrical power by converting sun energy into electricity. Second uses sun energy to heat up water tank and produce hot water in a building. In this article I will be talking about the first – Solar Photovoltaic (PV) panels as they are closely related to solar flood lighting. So further in article the term „solar panel” is going to be used to describe a solar photovoltaic panel.

Why solar energy?

First of all, the sun is tremendous energy source. The amount of energy that the sun transmits to the earth in an hour is enough to provide energy to whole world for one year. Sure, it is not possible to collect all this energy and convert it into power we need, but people are getting closer to using solar energy as our primary energy source. Solar energy has noticeable benefits over other energy sources. First of all, it is free for everyone. Of course free is probably not the correct word when describing solar energy, although we can get sun energy for free, we still need special tools to convert this energy to electricity or other useful type of energy, and these tools are definitely not free. Second, sun energy is independent and people do not need to depend on electricity prices dictated by government or private companies. Third, usage of the sun energy do not harm earth almost in any way, we reduce carbon emissions, pollution, and do not consume the Earths valuable resources.

Currently, sun energy can be transformed into electricity using photovoltaic solar panels. Solar panels are combined from multiple solar cells and mostly are used in groups to provide electricity for solar systems. These solar systems are mostly used to generate electricity for home usage and solar panels are installed on the roof. Also, as we know, smaller solar panels are used to power different electronic devices and tools. The simplest example would be a calculator that works with solar energy. Today, solar panels are common option for outdoor lighting, portable music players, portable chargers and other electric appliances we use every day.

Solar panels are still in a continuous development process and scientists are looking for ways to improve their efficiency and lower manufacturing costs, and they are also searching for new materials that can improve efficiency of a solar cell. The current technology mostly involves using crystalline silicon forms and silicon is used in 90% of solar panels produced. Also, latest technology thin-film modules are becoming more popular as they cost cheaper to make and can also be made flexible, which allows to use them in portable applications.

Now, let’s find out how PV solar panels work.

How solar panels work

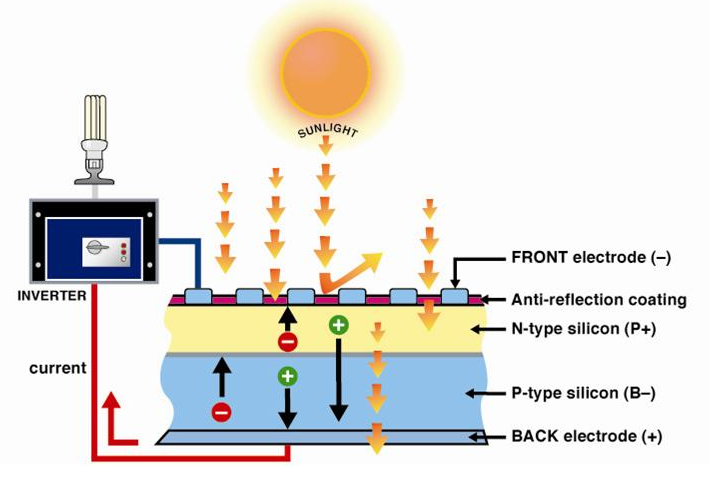

Most solar panel cells are made from crystalline silicon. Silicon is actually the second most abundant element in the Earth’s crust and can be found in dusts and sands. Solar panels uses photovoltaic effect to generate electricity from the sun light. Here are the basics of how solar cells and solar panels work.

- First, silicon is obtained from sand, quartz, rocks and other minerals. After that silicon is purified, so it can be used for semiconductors. For usage in solar cells silicon must have purity of more than 99.9%.

- Solar cell consists of two silicon panels – one n-doped layer and other p-doped layer. Silicon is doped (typically with boron (p) and phosphorus (n)) to create p-n junction, which established an electric field across the junction. Basically, solar cell consists of two silicon layers – one n-doped (negative) and other p-doped (positive) layer. Electric field is created between these layers, same as in a battery.

- Sun light consists of photons. When photons reach solar cell, an electric field is created across both layers.

- This electric field allows electrons to flow in a certain direction making electric current. So photon energy makes electrons become free, they flow to the bottom of the solar cell and exit trough wires. And so as the sunshine that reaches the panel gets stronger, more electricity will get produced.

- A solar panel consists of multiple solar cells mounted together in panels or modules. These modules usually are mounted on the roof of a building or on the ground. Multiple solar panels together can generate significant amount of electricity that could provide energy for electric appliances across the house.

To determine the output power of a solar panel a term „nominal power” is used. Nominal power is determined by measuring electrical current and voltage of solar panel under very specific lab conditions and international norms. Panel is put under full solar radiation and maximum generated power is determined. The nominal power is measured in Watt peak (Wp) or kilowatt peak (kWp). „Peak” means that solar panel has generated this power under optimal conditions, which cannot be reached under actual conditions, so in practice nominal power value will be over 10% lower than under optimal conditions. These nominal power ratings are useful, when comparing different solar panels and choosing the right panels for usage on roof of a house or other places.

What materials are used?

Solar cells are made from layers of semiconductor material, which usually is silicon. Silicon is one of the most common elements on the earth and is used in most PV cells. Crystalline silicon is used in monocrystalline and polycrystalline solar cells, which are the most commonly used across different application. In thin-film solar cells different materials than silicon are used. Most solar cells have protective glass layer on the front that protects them from outer elements and insulating layer with a back sheet on the back of the cell. Because silicon is shiny material, a special antireflective coating is applied to the surface of the cell to improve efficiency of the cell. Conducting wires can be made from different transition metals like silver or copper. Multiple individual PV cells are connected together in a grid to get appropriate voltage and current. These cells are put into a hard frame, usually made from aluminum that strengthens the panel and protects it from different impacts and allows mounting the solar panel in different ways, for example, on a roof of a house.

Solar system used in a house requires a special inverter that inverts DC current to AC that can be used to power different electric appliances in a house.

Thin-film solar panels can use other materials besides silicon, or combinations of silicon and different materials. Thin-film cells are created on a glass substrate. The most common types of thin-film solar cells are:

- CdTe – Cadmium telluride;

- a-Si – Amorphous silicon;

- CIGS – Copper indium gallium selenide;

- OPV – Organic photovoltaic cell or organic solar cell.

Types

As stated in the beginning of this article, active solar panels can be divided into two categories – solar photovoltaic and solar thermal panels. Solar photovoltaic (PV) panels are used to generate electricity from the sun light and solar thermal panels are using solar energy for heating water tanks to produce hot water. We are going to look at solar PV panel types in more details as they are used to generate electricity and are closer related to solar lighting.

Currently, there are four different solar PV panel types used to produce electricity from the sun energy. These types are:

- Monocrystalline Silicon

- Polycrystalline Silicon

- Thin-film solar cells

- BIPV or building integrated photovoltaics

Two of the most popular types of solar panels are monocrystalline and polycrystalline silicon solar panels.The core of both of these solar panels are made from silicon crystalline. Thin-film solar panels are also becoming more popular each year by the progression of their manufacturing technologies. BIPV can be monocrystalline, polycrystalline or thin-film solar panels that are integrated into buildings as tiles, roofs, windows and other objects. Now in more details about each type of solar PV panels.

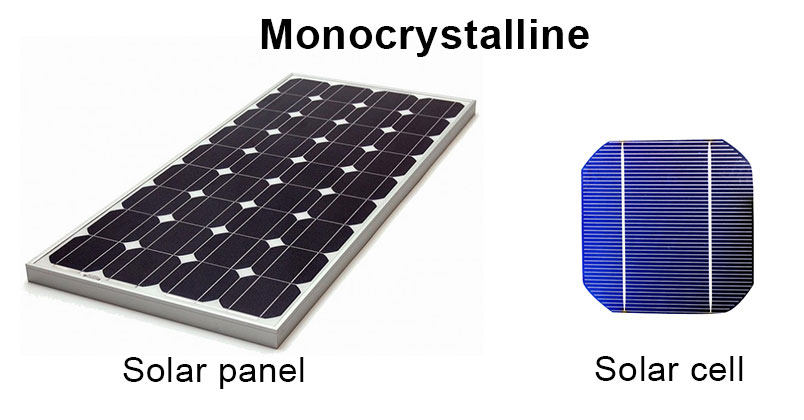

Monocrystalline Silicon

Monocrystalline silicon panels are the most efficient of all solar panels. Efficiency of monocrystalline cells currently is 15-21%. However, single crystalline panels are also the most expensive ones, because lot of silicon crystalline must be used in solar cells. Monocrystalline solar panels are considered to be the first generation of solar panels and have been known for more than 50 years.

Monocrystalline silicon is a semiconductor. It is made from pure silicon and contains extremely small amounts of other elements. Silicon monocrystals are grown in a process called Czochralski process. In result of this process, large, cylindrical shaped ingot is formed. This ingot is then sliced into thin, round wafers and trimmed into a square shape, so they can be easily arranged into solar panel.

Advantages of monocrystalline silicon solar panel

- Monocrystalline silicon panels are the most energy efficient of all solar panels. This means that monocrystalline panels require less space than same power polycrystalline or thin-film panels.

- Monocrystalline silicon panels have long lifetime. Manufacturers usually offer 25 year warranty for these solar panels.

- These panels perform better in lower light conditions.

- These panels have nicer look than polycrystalline panels with their dark color cells.

Disadvantages of monocrystalline silicon solar panel

- High costs are the main disadvantage of these panels. Monocrystalline panels are more expensive to make, so their price is also higher than polycrystalline or thin-film panel price.

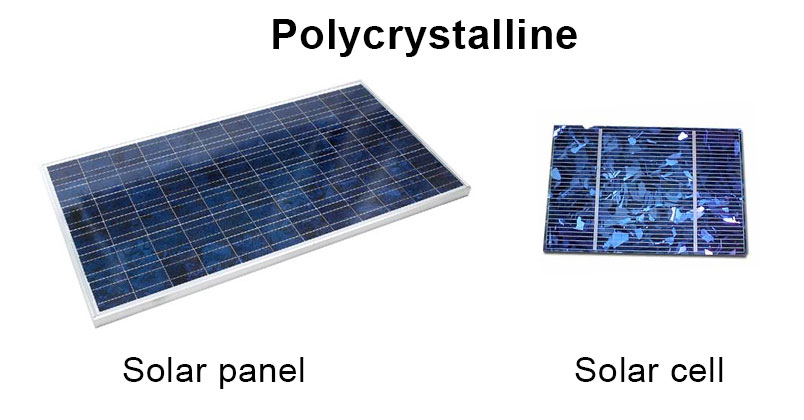

Polycrystalline Silicon

Polycrystalline silicon panels are second most used solar panels after monocrystalline. Efficiency of polycrystalline silicon cell is approx. 13-16%, which is less than single crystalline solar cell efficiency. However, polycrystalline solar panels are less expensive than monocrystalline and because of that they are sometimes considered to be a better solution in different applications.

Polycrystalline cells are made from the same silicon as monocrystalline cells, however, instead of making a large ingot of silicon crystalline, silicon is melted and poured into a special square form, which is then cut into smaller wafers. Production of polycrystalline silicon cells wastes less material, because cells do not need to be cut into square shapes as in production of single crystalline cells.

Advantages of polycrystalline silicon solar panel

- The price of polycrystalline panel is cheaper than price of monocrystalline panel and less silicon is used to make a polycrystalline panel.

- The process of producing polycrystalline silicon cells is simpler and cost less than production of single silicon cells. Also the amount of silicon wasted is less compared to monocrystalline panel production.

Disadvantages of polycrystalline silicon solar panel

- These panels are less energy efficient than monocrystalline panels. This means that to output same amount of power, a polycrystalline solar panel is going to take more space than monocrystalline solar panel.

- In opposite to monocrystalline and thin-film cells that have dark, black color, polycrystalline cells have varieties of dark, blue color and do not look as good as other two solar panels.

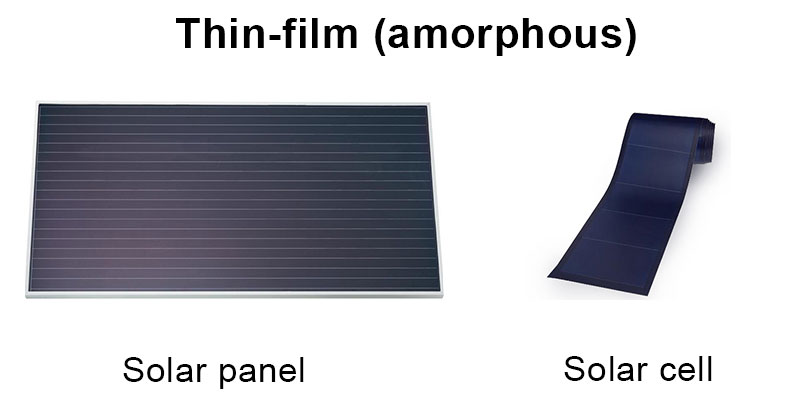

Thin-Film Solar Cells

Thin-Film solar cells are made by depositing thin layers of photovoltaic material on a substrate. Thin-Film solar cells may use silicon or other substances as active material. Thin-Film cells are currently less efficient than monocrystalline or polycrystalline cells with efficiency of approx. 10% depending of the technology and material used in a thin-film cell. However, thin-film solar technologies are still in a development process, and we are probably going to see huge improvements of this solar technology in the near future.

Currently, the four most known materials used in thin-film cells are: Cadmium telluride (CdTe), Copper indium gallium selenide (CIGS), amorphous silicon (a-Si), Organic photovoltaic cells.

Advantages of Thin-Film solar panel

- Thin-Film solar panels are cheaper and simpler to make than crystalline solar panels.

- Thin-film panels can be made flexible, which will allow to use them in future electronic appliances.

- Their simple and even look makes them better looking than crystalline solar panels.

- Flexibility, light weight and low thickness allow integrating these panels into different building installations.

- High temperatures do not affect thin-film modules as much as crystalline modules. When temperature gets higher than 25 degrees C, crystalline solar panels start to produce less energy. When temperature reaches over 50 degrees C, they can produce dramatically less electricity. The performance of thin-film panels are not affected as much.

Disadvantages of Thin-Film solar panel

- Thin-Film solar panels currently are less efficient than crystalline panels. This means that you will need more space and more thin-film solar panels to produce same amount of electricity as polycrystalline or monocrystalline panels.

- Total cost of setting up thin-film solar panels that produce useful amount of electricity can rise significantly, because up to 4 times more space and equipment is required to install thin-film panels than monocrystalline panels that can produce same amount of electricity. This also levels the cheaper price of thin-film panels.

- Thin-Film panels cannot provide the same longevity as crystalline panels. Thin-film is a relatively new technology and different materials are used in production of solar cells for these panels. There is a possibility that thin-film cells will degrade faster after some time of usage. This is why manufacturers usually do not provide the same 25 year warranty as crystalline panels for thin-film panels.

BIPV (Building Integrated Photovoltaics)

BIPV or building integrated photovoltaics are solar photovoltaics that are integrated into the building in form of solar shingles, solar tiles, slates and others. This type of PV can be integrated into roofs, facades and even windows. BIPV are becoming more and more popular and are being used in many newly built buildings like large office centers to help save more energy and generate some volume of electricity needed for the building. However, BIPV have some visible disadvantages compared to building-applied photovoltaics. BIPV can cost a lot more than regular photovoltaics. However, they can cut down on expenses of other materials that might be needed for a new building in places, where BIPV are going to be used instead. BIPV are also less efficient and will usually have shorter lifetime.

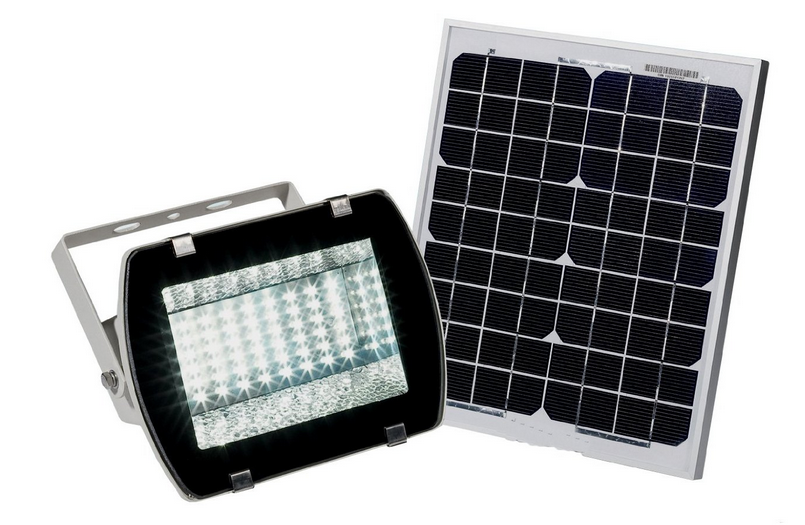

Solar panels in flood lights

Solar flood lights use the same solar cells that are used in large photovoltaic systems. Three most popular types of solar panels used to power flood lights are:

- Amorphous

- Monocrystalline

- Polycrystalline

In solar photovoltaic systems the most popular types of panels are monocrystalline and polycrystalline, because they are more efficient. Thin-film panels, which include amorphous panels, are less common in solar systems. In solar lighting, crystalline and thin-film panels are used at the same rate. Basically, you will find approximately the same amount flood lights with amorphous, monocrystalline and polycrystalline panels. Now let’s see for which flood lights each solar panel type is used.

Amorphous solar panels in flood lights

When looking at solar flood light market and analyzing what type of flood lights uses amorphous solar panels, it immediately becomes clear that these types of solar panels are used mostly on cheaper,”low end” flood lights. And it is pretty obvious, because amorphous photovoltaic panels, as previously mentioned, have the cheapest price and also costs less to manufacture than silicon crystalline panels. It makes sense to use these panels in “low end” solar flood lights, as it is a perfect way to cut down the price and make it more appealing to customers, sacrificing a little bit of its performance. However, amorphous solar panels are not only used by low range flood lights, but also in some medium quality lights. For example, the company Maxsa is using amorphous solar panels in their top quality solar flood lights that are highly valued by their users.

Typically, you will find amorphous solar panels used in flood lights at price range from 20 – 70 dollars, typically sold at 30-40 dollar price. These „low end” flood lights are usually made from plastic and casing for solar panel is also made from plastic. These flood lights are mostly used around the house to illuminate smaller areas, like for example front door.

Best known solar flood light companies that uses amorphous solar panels in their flood lights are Sunforce, Maxsa, Reusable Revolution, Solar Illuminations and others.

Monocrystalline and polycrystalline solar panels in flood lights

Silicon crystalline solar panels are also used in lot of flood lights. As we know, monocrystalline and polycrystalline panels have some significant advantages over thin-film panels. They are more energy efficient, so they need less space to produce the same amount of electricity as amorphous panels and this is perfect for flood lighting. Silicon crystalline panels also have longer lifetime and their efficiency will not drop for over 20 years. But the main disadvantage of these panels is their cost. Mono and poli-crystalline solar panels cost significantly more than amorphous solar panels. This is the main reason, why you will mostly find silicon crystalline photovoltaics in “midrange” and “high end” floodlighting.

When we talk about large solar modules used to power buildings, monocrystalline panels are more effective and also cost more. Polycrystalline panels are little bit less effective and also they are cheaper. So, if we apply this to solar lighting, it would make more sense, if monocrystalline panels were used for the most expensive and powerful “high end” flood lights and polycrystalline panels for less demanding, “mid-to-high end” flood lights. In practice, there isn’t actually a big difference whether mono or poly-crystalline panels are used on a flood light. The reason is simple, the difference in efficiency between monocrystalline and polycrystalline cells is actually not that large, and it can be better seen when there is need for multiple large solar panels to provide electricity for a building. For solar flood lights usually a single small sized panel is used (or single or double larger solar panels for high power flood lights). In such small appliances as flood lights there is practically no difference whether monocrystalline or polycrystalline panel is used. Which panel is used in which flood light depends on preferences of each manufacturer. Some solar flood light manufacturers use only monocrystalline panels, others polycrystalline, and there are even some flood lighting manufacturers like Solar Illuminations that are using all three types of solar panels in their products.

Interesting thing to note is that monocrystalline and polycrystalline solar panels can also be found in “low end” flood lights, although they are used in much less „lower end” flood lights than amorphous panels because of their higher cost. Mostly you will find monocrystalline panels in flood lights at 100 dollar range, but they can also be found in powerful, “high end” flood lights costing couple hundred to thousand dollars. Polycrystalline panels are usually used in flood lights that cost over 100 dollars up to 500 dollars. These “high end” solar flood lights are mostly made with metal casing that can protect the lighting fixture and solar panels, so they can be used outdoors in any weather conditions. Powerful, “high end” flood lights are mostly used to illuminate large areas like sports fields, parking lots, backyards and also are used as decoration lights to illuminate statues, monuments, prominent buildings and other places. Best known solar flood lights manufactures that uses monocrystalline panels are eLEDing, Reusable Revolution, Solar Goes Green, XEPA, Solar Illuminations an others. And best known solar flood lights manufacturers that uses polycrystalline panels are MicroSolar, Solar Goes Green and Solar Illuminations and others.