HID Lights for Beginners – High Intensity Discharge Lamps Explained

When talking about household lighting, especially light bulbs used for indoor lamps, most people are familiar with incandescent, halogen, compact fluorescent and LED bulbs. But are the same type of bulbs also found in high wattage outdoor lights, for example in street lighting or flood lights used to illuminate football stadiums?

The simple answer is no. Those regular bulbs used in ceiling lamps or kitchen lighting cannot handle very high voltages and produce many thousands lumens of light.

For applications where high brightness is required to illuminate large areas, for indoor plant growing and for other similar cases, a specific type of bulbs are required. The most common of these are:

- Fluorescent lights (used indoors);

- LED lights (while LED bulbs are also widely used as household lighting, there are special high wattage LED lights suitable for illuminating large areas);

- HID or high intensity discharge lights (which we will cover in this article).

There are three main categories of light bulbs:

- Incandescent bulbs that emit light by heating tungsten filament until it starts to glow (incandescent and halogen bulbs);

- Gas discharge lamps that produce light by creating an electric discharge through ionised gas (high intensity discharge bulbs and low intensity discharge bulbs);

- Light-emitting diodes where light is generated by passing current through a semiconductor material (LED lights).

Before we go into details with low and high intensity discharge bulbs, we need to understand what a gas discharge lamp is.

GAS DISCHARGE LAMPS

While almost anyone knows what are incandescent bulbs, not so many know what are gas discharge lamps, although they had (and still have) an important role in indoor and outdoor lighting. Some gas discharge lamps may look more similar to incandescent lights, while others, such as fluorescent lights, can have completely different size and shape.

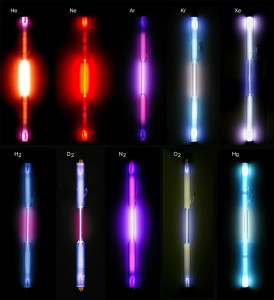

The working principle of gas discharge lamps is very different from incandescent bulbs, instead of heating a filament to produce light (which is not very effective, because a lot of energy gets wasted as heat), they produce light by creating an electric discharge through an ionised gas. This allows to create light at various colors, depending on the type of gas used in the lamp or the inner coating of the tube, and also notably improves the efficiency and lifetime of the bulb. Gas discharge lamps also require special ballasts to control current flow supplied to the lamp.

Gas discharge lamps can be separated into two categories by the pressure of the gas inside of the lamp – high pressure gas discharge lamps and low pressure gas discharge lamps.

High pressure discharge lamps

High pressure discharge lamps contain pressurized gases such as argon, xenon, neon, krypton, mercury, sodium and others inside a small arc tube located in the lamp. Gas inside high pressure discharge lights has similar or higher pressure (up to 30 Bar and more) than atmosphere (approx. 1 Bar) and some of these lamps operate at very high temperatures up to 3000° C (5400° F). Because of the high pressure and intense discharge, these lights can be made in a smaller size than low pressure discharge lamps.

Thanks to their power and brightness, high pressure discharge lamps are used to illuminate large indoor and outdoor areas such as stadiums, arenas, warehouses, parking lots, shops and others. Examples of high pressure discharge lamps are mercury vapor lamps, high pressure sodium vapor lamps and metal halide lamps.

Low pressure discharge lamps

Low pressure discharge lamps have gas inside the bulb in much lower pressure (about 30 milli Bar for fluorescent lights) than atmospheric pressure (approx. 1 Bar) and they operate at moderate temperatures at about 40° C (104° F).

Low pressure discharge lamps are known for their high energy efficiency, so bulbs such as fluorescent and compact fluorescent are commonly used in household and office lighting. Some examples of low pressure discharge lamps are previously mentioned fluorescent lamps, low pressure sodium lamps (which are one of the most efficient artificial light sources) and neon lights.

High intensity discharge lamps is another category of gas discharge lamps. These lights work by creating an electric arc between electrodes (usually made from tungsten) located in a semi-transparent or transparent arc tube. The most common examples of high intensity discharge lamps are metal halide lamps, sodium vapor lamps, mercury vapor lamps and xenon arc lamps.

Now lets look specifically at high intensity discharge or HID lights.

HIGH INTENSITY DISCHARGE LAMPS

What are HID lights?

HID or hight intensity discharge lights are a type of gas discharge lamps which produce light by creating an electric arc between two electrodes through an ionised gas. Electrodes, gas and metal salts (for some HID lamps) are hermetically sealed inside a special arc discharge tube made from quartz or sintered alumina.

HID lamps also have an outer glass bulb that protects the inner parts of the bulb, blocks ultraviolet light on some bulbs types, keeps more heat inside the bulb and protects people around, if the lamp was to explode and break.

HID lamps don’t need any coating inside its tubes because the arc itself emits visible light, unlike fluorescent lights that have phosphor coating that glows when UV light strikes it. However, few metal halide and lots of mercury vapor lamps have phosphor coating inside the bulb to improve the light spectrum and color rendering of the lamp.

High intensity discharge light bulbs come in wattages from 25 watts for self ballasted metal halide lamps and 35 watts for high intensity sodium vapor lamps to 1000 watts for high intensity mercury vapor and sodium vapor lamps and 1500 watts for metal halide lamps.

One thing that differs gas discharge lamps from other type of bulbs such as halogen is that they require special control gear called ballast to operate. Ballast performs certain functions such as regulates the amount of current supplied to the inner tube of the bulb, ignites the light and supports other functions such as dimming the lamp.

How do HID lights work?

The working principle of each type of high intensity discharge lamp is a bit different, but they share some similarities that will be covered next. For how each specific type of HID light works, head to the paragraphs dedicated specifically to each type of HID lamp (Mercury vapor lamp | Metal halide lamp | High pressure sodium lamp).

- Every HID lamp consists of an arc tube which is filled with gas, what type of gas is used depends on the type of HID lamp, for example metal halide lamp can contain a starting gas such as argon, mercury and metal salts, while a high pressure sodium lamp can contain a xenon gas, mercury and sodium. Inside the arc tube are two main electrodes (mostly made from tungsten), the tube itself is usually made from quartz to withstand the excessive heat that develops while the lamp operates. Most bulbs have an outer glass to improve protection and efficiency of the bulb.There is also a ballast for each HID lamp that controls the current that gets passed to both electrodes, ballasts are required to start the lamp and ensure it operates correctly.

- The first step for light to work is to start a current flow between both tungsten electrodes through the gas. Because there is a high pressure inside the arc, a very high voltage is required to start the current flow. On some HID lamps a special igniter is used that pulses the arc tube with high voltage until it strikes. When the current flow between both electrodes has been established, the voltage is reduced. The current is controlled by the ballast of the lamp.

-

An arc is created between both electrodes that will be used to vapourize mercury, sodium, metal salts (or other substances depending on the type of the lamp) inside the quartz tube and produce intense light.

- The gas inside the tube is ionised and acts as a conductor. Free electrons flow between both electrodes in the electric field and collide with gas molecules, knocking electrons into a higher level, when they go back into the previous level, they emit energy in form of radiation. The color of the light will depend on the type of metal vapor used in the lamp. What differs low pressure discharge and high pressure discharge lamps is that the second ones have much higher concentration of excited molecules in the tube, so in result they can produce much brighter light.

- When the arc has been created and lamp is operating, the temperature and pressure inside the tube builds, which also heats the metal salts located in the tube, this eventually increases the intensity and brightness of the light produced by the lamp. Most HID lamps such as sodium vapor require few minutes of start-up time until the heat and pressure inside the tube is high enough for the lamp to reach the maximum brightness (in case of sodium vapor lights for sodium to vaporise).

- The color and intensity of the light and also the efficacy of the lamp will depend on various factors such as the type of gas (xenon, argon etc.) and metals (mercury, sodium etc.) used in the lamp and the heat and pressure inside the tube. To improve the color of the lamp other metal salts can also be used inside the tube.

- If HID lamp has been running for a while and reached its optimal temperature and then is turned off, most HID lamps cannot be instantly turned on again, as they need to cool down before they will re-strike, the cooling process can take even up to 10 or 20 minutes depending on the type of HID lamp.

- HID lamps generally have good life span, especially when compared to halogen or incandescent lights. The average lifespan of mercury vapor lamps is about 24000 hours, of metal halide about 10000 – 15000 hours and of high intensity sodium vapor lamps about 10000 – 24000 hours. The lifespan of a HID lamp depends on the total amount of on time and number of on/off cycles, similar to other gas lamps.

At the end of the life, HID bulbs start to act differently, for example, some bulbs, as they get older, require higher voltage to maintain an electric arc between electrodes which increases the heat inside the tube. In a result, the fixture turns off and needs to cool down before it can turn on again. This process will repeat more frequently as the lamp gets older.

Also, when a HID lamp gets closer to the end of its life, it can start to loose color of the emitted light or in other words, start to fade. The process also happens because the lamp needs higher voltage to operate, which increases the temperature inside the discharge tube and results in a failure of the lamp.

Video showing how a high pressure sodium lamp warms up and changes color while elements inside the arc tube vaporize. The first element that glows is xenon in sky blue color, next is mercury in bluish green color and last is sodium in orange color.

HID ballasts

HID lamps, similar to fluorescent lamps, require a ballast to operate. The main functions of a ballast in a HID light is to start the lamp and control the current supplied to the lamp so it can maintain an arc between both electrodes, or in other words, it controls how the lamp operates. A HID light can have either an electronic or a magnetic ballast, in addition the ballast has a capacitor for converting volts and amps into power and in some fixtures an igniter and pulse start system to start the lamp.

Basically, how a HID ballast works is it provides enough voltage to strike the arc using a striker which is integrated in the ballast itself, the higher voltage must be supplied until an arc has been established, after that the voltage is reduced to the level necessary to maintain the arc.

The method used to strike a HID lamp differs based on the type of the lamp, for example, mercury vapor lamps are started using a third electrode that is located close to one of the main electrodes, but high pressure sodium lamps, on the other hand, are mostly started producing pulses of very high voltage.

Once the arc has been stablished, the main function of the ballast is to limit the current output, obtaining the optimal working temperature of the light and cutting off the power, incase the voltage and the heat inside the tube gets too high, to prevent the lamp from failing and possibly exploding.

Besides striking the lamp, a ballast performs few additional functions such as controlling the output and brightness of the lamp. Ballasts also have to know when to re-strike a bulb that had been working at optimal temperature before it turned off, because not all types of HID lamps can be restarted instantly and some lamps require a cool down period.

It is important for a ballast to keep the voltage and temperature of the lamp at the optimal performance range, which guarantees that the lamp produces light at the proper color temperature and also ensures the lamp reaches its rated life time. For a HID lamp to work properly, the correct type of ballast must be used that matches the electrical requirements of the lamp.

HID light types

There are various types of high intensity discharge lamps, all of which differ by compounds used to produce the light – mercury, sodium, metal halide or mixture of few. According to these compounds, 3 of the most common HID light types are:

- Mercury vapor lamps;

- High pressure sodium vapor lamps;

- Metal halide lamps.

Based on the chemicals used in these lamps, each HID lamp has different specifications, starting from efficacy, brightness and color temperature, to color rendering index and lifespan of the lamp.

Next, we are going to look in more details at three of the most common HID light types: mercury vapor lamps, metal halide lamps and sodium vapor lamps.

MERCURY VAPOR BULB

Description and usage of mercury vapor lamps

Mercury vapor lamp is the oldest type of high intensity discharge lamp, it has been around for more than 80 years and had an important role for lighting up large areas such as factories, streets and other areas.

There are two types of mercury vapor lamps – low intensity discharge and high intensity discharge. First successful low intensity discharge mercury vapor lamps was invented in 1901 by an American engineer Peter Cooper Hewitt, but the first HID mercury lamp was developed later, in 1936. Higher pressure inside the bulb helps to increase the efficiency of the lamp and also decreases its dimensions.

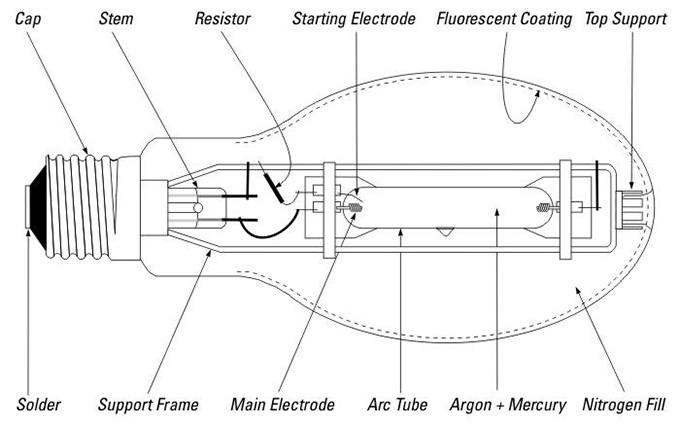

The lamp creates light by producing an arc between two electrodes through vaporized mercury in a high pressure tube made from fused quartz. Because the lamp operates at a high pressure, it can produce light directly from the arc. The discharge tube is covered by a larger glass bulb which is serving the purpose of insulating the heat inside the tube for better performance and protecting everything outside the bulb from ultraviolet radiation.

The outer bulb can be either clear or coated with a phosphor cover to improve the color rendering of the lamp. Clear mercury lamps produce light in blue to green colors which don’t have a good color rendering and objets below such lights tend to look greener. Adding a phosphor coating to the outer bulb improves the color rendering and makes color of objects in the light to appear more natural.

High intensity mercury vapor lamps were mostly used as a street lighting in early days, but have been widely replaced by sodium vapor lights or recently by led flood lights. Because of the long life span of up to 24000 hours and high intensity, these lights were also used to illuminate large indoor areas such as factories, arenas, warehouses and similar. Today, other types of HID lights such as sodium vapor and metal halide and also LED lights have replaced the older mercury vapor lamps in most applications due to higher efficiency, better color rendering, increased durability and safety, and longer life span. However, mercury vapor bulbs are still used in applications such a landscape lighting, parking lot lighting and in security lighting.

Mercury vapor lamp specifications

- Efficacy – about 30 – 60 lumens per watt, depending on the ballast;

- CRI – poor CRI of 20 for clear bulb, and improved CRI of 40 – 60 for phosphor coated bulb;

- Color Temperature – 6000K – 6800K for clear bulb and about 4000K for phosphor coated bulb;

- Life span – approx. 24000 hours on average;

- Available wattages – from about 50 – 1000 watts;

- Restart time – restart time for a hot lamp can take between 4 – 5 up to 8 – 10 minutes.

How do mercury vapor bulbs work

The arc tube of a mercury vapor lamp is made from fused quartz glass that can withstand extremely high temperatures.

Inside the arc tube are two main electrodes made from tungsten, and near the main electrode that is located closer to the ballast is a starting electrode used to start the arc, it is connected to the other main electrode through a resistor. Starting electrode helps to reduce the amount of voltage the lamp requires to start.

The arc tube is filled with argon gas that is ionised to create arc and solid mercury that gets heated and vaporizes as the pressure and heat inside the tube increases. The argon gas strikes quickly but it can take few minutes until the mercury vaporizes and produces intense light in a bluish color.

The outer bulb that protects the inner parts is made from a borosilicate glass and may be coated with a fluorescent coating to improve the color rendering of the lamp. Ballast is used to limit the current passed to the arc and prevent lamp from breaking.

Advantages of mercury vapor lamps

- Lifespan – The main advantage of mercury vapor lamps is their long lifespan, on average the lamp can provide up to 24000 hours, but there are known cases when these types of lamps have lasted for more than 20 years in operation. In comparison, the average lifetime of halogen bulbs is only 2500 – 3500 hours, CFL bulbs – 15000 hours, Metal halide lamps – 10000 – 15000 hours, HPS lamps – 24000 and LED bulbs – over 25000 hours.

- Efficiency (when compared to certain bulb types) – Mercury vapor lamps also have quite good efficiency of 30 – 60 lumens per watt. This is 2 – 4 times higher than efficacy of incandescent bulbs and halogen bulbs and can even match metal halide lamps and some fluorescent light bulbs. However, when they are compared with direct rivals in outdoor lighting – high pressure sodium and LED, mercury vapor lamps cannot compete with them in terms of energy efficiency.

- Price – High pressure mercury vapor bulbs are pretty cheap, making initial costs of the lamp low.

- Color rendering (for improved lamps) – Although high pressure mercury vapor lamps are not known for their ability to render colors properly, there are improved models with phosphor coating for better color rendering of the lamp. These lamp have better color rendering than high and low pressure sodium vapor lights, but they cannot compete with metal halide or halogen lamps. They produce bright, intense white light which is good for outdoor use.

Disadvantages of mercury vapor lamps

- Toxic mercury – Similar to other gas discharge lamps such as fluorescent lights and other HID lamps, mercury vapor lamps also contain small portions of the toxic element – mercury, which makes the disposing process more difficult.

- Poor color rendering (when compared to competing light bulbs) – Although there are types of mercury vapor lamps with phosphor coating that have improved color rendering, regular mercury vapor lamps render colors very poorly, objects under these lights tend to look bluish or green. Because the human skin under these lights look in an unhealthy green color, is why these lamps aren’t typically used indoors or in film and photography. Other types of bulbs such as incandescent, halogen, metal halide and even LEDs offer much better color rendering and so are replacing mercury vapor lamps in many applications.

- Efficiency (for high power lighting) – The efficiency of mercury vapor lamps is actually quite good when compared with tungsten filament bulbs and even some fluorescent lights, however, when it comes to high power outdoor lighting, metal halide, high pressure sodium and LED bulbs can still offer better luminous efficacy than mercury vapor lamps.

- More expensive to run than metal halide, high pressure sodium or LED lights – Because of the lower lumens per watt rating, mercury vapor lamps will consume more energy to output the same amount of light and in result will add up to the electricity bill.

- Cannot maintain constant luminous flux throughout the lifetime – Mercury vapor lights will get dimmer as they get older, so they are not useful for places where constant brightness is needed all the time.

- Warm-up and restart time – There is a warm-up time of few minutes to start the lamp and also 4 – 8 minutes restart time if the lamp has been running at optimal temperature.

- Durability and safety – Mercury vapor, similar to other gas discharge lamps, have problems with durability as they can easily be broken (LED lamps are a lot more durable). Also, because the bulb contains mercury which is highly toxic to humans and animals, it should be disposed properly to avoid any safety risks.

- Government restrictions – There are certain government restrictions in many countries made to phase out mercury vapor bulbs to support usage of newer and more efficient lighting technologies such as LED.

METAL HALIDE LAMP

Description and usage of metal halide bulbs

First stable metal halide bulbs that could stand higher operating temperatures were invented in early 1960s by Robert Reiling who improved the previous experiments of Charles P. Steinmetz. Later, metal halide lamps became one of the main artificial lighting sources to be used for illuminating large areas both indoors and outdoors.

As metal halide lamps basically originated from mercury vapor bulbs, the construction and in some ways also their looks are pretty similar to mercury vapor lamps. Metal halide lamps are high pressure discharge lamps that produce light by creating an electric arc through vaporized mercury (similar to mercury vapor lamps) and metal halides such as silver iodide, silver bromide sodium iodide and others. These metal halides help to achieve higher light output, better efficiency and improve color rendering, making MH lamps in many ways superior to mercury vapor lamps.

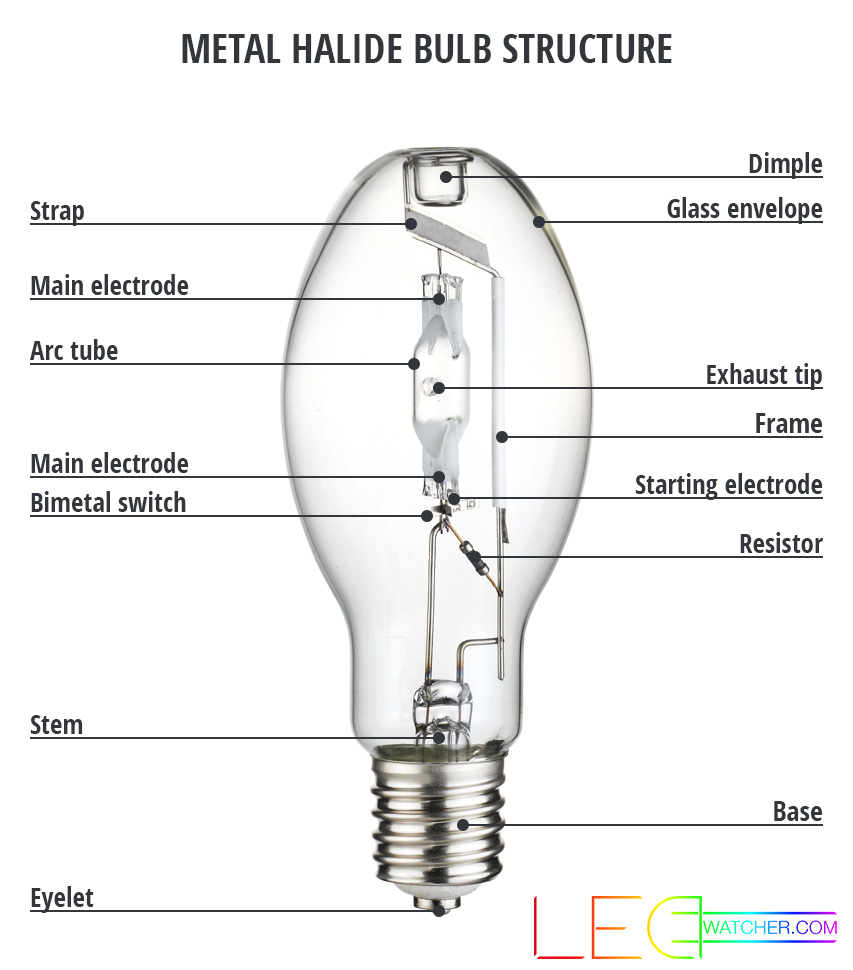

The metal halide bulb consists of a compact arc tube located inside a larger glass bulb. The arc tube itself is made from fused quartz to withstand the high operational temperatures created from the high pressure (up to 50 and more psi) inside the arc tube.

Inside the arc tube there is a mixture of argon gas, mercury and halide salts. At first, the discharge happens through the gas till the tube heats enough for mercury to vaporize. While mercury vaporizes the temperature inside the tube keeps building until all metal salts inside the tube vaporizes too, each giving off a different color. The combination of these colors makes the metal halide lamps produce intense, white light at color temperatures around 4000K.

Metal halide lamps are almost twice as efficient as mercury vapor lamps, but not as efficient as high pressure sodium lights. A 400 watt metal halide bulb will produce around 38000 lumens, while the same wattage HPS lamp can produce up to 50000 lumens.

However, metal halide lamps have the shortest lifespan of high intensity discharge lamps, loosing to both mercury vapor and HPS lamps. On average, the lifespan of a metal halide lamp is from 10000 to 20000 hours.

Because of such advantages as good color rendition, production of very clean, white light and high lumen output, metal halide lamps are used in large variety of applications both indoors and outdoors. Here are some of the most common uses of metal halide lamps:

High bay lighting for large indoor areas:

- Large sports arenas, athletic facilities and gymnasiums;

- Factories and other industrial areas;

- Auditoriums;

- Halls;

- Stages;

- Lower power lamps are used in retail stores and other commercial buildings;

- Other commercial, public or industrial areas.

Floodlighting in outdoor areas:

- Parking lots;

- Open sports arenas and stadiums;

- General public spaces such as parks, although lamps such as high pressure sodium and LED are mostly used in such areas.

In automotive industry:

- In car headlights, often referred as HID headlights or xenon headlights. This is because the gas inside the arc tube of these headlights is xenon instead of argon used in general purpose metal halide lamps. These xenon HID lamps are more compact, work at even high pressure, are more efficient and produce more lumens than regular metal halide lamps.

Speciality lighting in different industries:

- Television and film making;

- Photography;

- Indoor growing applications;

- Security lighting for residential applications;

- Diving, thanks to its high light intensity.

Metal halide lamp specifications

- Efficacy – about 65 – 115 lumens per watt;

- CRI – from 60 – 95 for ceramic metal halide lamps;

- Color Temperature – 3000 – 4000K, however some lamps can go up to 20000K;

- Life span – approx. 10000 – 15000 hours on average;

- Available wattages – from about 20 – 3000 watts and more;

- Restart time – restart time for hot lamp can take from 5 – 10 minutes (there are special lamps that can restrike instantly);

- Luminous maintenance – the luminous maintenance of older metal halide lamps is about 60% and newer can reach up to 80 – 90%;

- Operation position – Mostly vertical, but there are also lamps made specifically for horizontal usage. Vertical lamps used horizontally will have approx. 2 times shorter life span.

How do metal halide lamps work

The structure of a metal halide lamp consists of a small arc tube made either from quartz or sintered alumina ceramic, inside of the arc tube contains a gas, mercury and metal halides. The discharge tube is enclosed inside a larger bulb made from glass, similar to mercury vapor bulbs, which protects the smaller parts from outer impacts and helps to keep more heat inside the bulb, as well as can be used to block ultraviolet radiation generated inside the lamp.

The discharge arc tube has both ends sealed with two main electrodes made from tungsten residing at both ends. Next to one of the main electrodes is a starting electrode and resistors used to start the lamp.

Ends of most metal halide bulbs are coated with ceramic to reflect the heat back to the lamp and keep the arc at a specific temperature needed for halide salts to vaporise. Keeping a higher temperature inside the arc tube allows the lamp to be brighter, more efficient and also improves the color rendering.

Metal halide, similar to other high intensity discharge bulbs, require electric ballasts to operate safely.

The light in metal halide lamps are generated through a high pressure gas discharge inside the arc tube, this process happens between two tungsten electrodes on each side of the arc tube. The discharge arc is generated through the argon gas (in most lamps), so it must be made conductive by a process called ignition, when high-voltage pulses are generated by an ignition device.

When the lamp starts through the argon gas, the tube is still cold, so the lamp is very dim and produces blue color. When the lamp heats up, the mercury slowly starts to vaporize making the arc produce brighter and more intense light and at the same time reducing the size of the arc.

When enough heat is generated inside the arc tube, the various halide salts start to vaporize too, each producing a different color from white to green and yellow. In combination with the blue color of mecrury and various colors of halide salts, the lamp starts to shifts its color from blue to white.

All this process requires some time (usually few minutes) for mercury and all halide salts to fully vaporize and for the lamp to reach its full brightness. This process is called warm-up period.

When a metal halide lamp reaches the end of its lifespan, it starts to change the color of the light, the brightness of the light reduces and lamp starts to go off after some period of illumination till it cannot be ignited at all.

Advantages of metal halide lamps

- High efficiency – One of two main advantages of metal halide lamps are their high energy efficiency, producing approx. 65-115 lumens per watt, which makes them more efficient than incandescent, halogen, fluorescent and also mercury vapor lamps.

- Excellent color rendering – The main advantages of metal halide lamps are their excellent color rendering that for some bulbs goes as high as 95 CRI. These lamps are an excellent source of white light, emitting light close to a natural sunlight, which makes them great for both indoor and outdoor areas.

- Large variety of color temperatures – Standard metal halide bulbs output color at 3000 – 4000K temperature, however they can be designed to output colors up to 20000K range which makes them perfect for all sorts of applications, including television, movie making, photography, diving, automotive industry and other specialities.

- Reasonable life span – Metal halide bulbs offer a reasonable life span of 10000 – 20000 hours on average, although it is still the shortest between high intensity discharge lights.

- Large variety of wattages and forms – Metal halide lamps are available at large variety of wattage and sizes, from compact 20 wattage bulbs to large and powerful 2000 watt high bay lamps, allowing to use metal halide lamps in large variety of indoor and outdoor applications.

Disadvantages of metal halide lamps

- Expensive – Metal halide bulbs can be expensive to manufacture, depending on technologies and materials used to produce the lamp.

- Can cycle and rupture at the end of life – Some lamps can start to cycle at the end of life or shift in color. Also, arc tube can rupture for some lamps, so these lamps are designed to be used only in enclosed fixtures.

- Shorter life span than other HID lamps – The average life span of a metal halide bulb is 10000 – 15000 hours which is lower than mercury vapor bulb’s 24000 hours and high intensity sodium vapor bulb’s 24000 hours.

- Higher lumen depreciation – MH lamps, especially the older models, suffer form high lumen depreciation, meaning that they will loose their initial brightness faster as the lamp operates. Older MH lamps provide luminous maintenance up to 60%, while newer and improved ceramic metal halides can keep up to 80 – 90% of their initial brightness through their life time.

- Toxic mercury – Similar to mercury vapor, HPS and fluorescent bulbs, metal halide bulbs also contain small portions of the toxic element – mercury.

- Warm-up and restart time – There is a warm-up time of approx. 10 min to start the lamp and also 5 – 10 minutes restart time if the lamp has been running at optimal temperature.

- More light pollution – Because of the high intensity and brightness of the light, metal halide lamps make more light pollution than other high intensity discharge lamps.

- Life span depends on orientation – Metal halide lamps are orientation sensitive, meaning that if you install a vertically designed bulb horizontally, it will reach the end of its life much sooner, sometimes even twice the time. To address this problem, manufacturers are producing lamps that are specifically designed either for vertical or horizontal positions.

HIGH PRESSURE SODIUM LAMPS

Description and usage of high pressure sodium bulbs

High pressure sodium lamps are type of gas discharge lamps that produce light using sodium in an excited state. There are two types of sodium vapor lamps – high pressure and low pressure. While low pressure sodium vapor lamps are known for their high energy efficiency and monochromatic light output, in this section we are going to look the second type of sodium vapor lamps – high pressure sodium vapor lamp.

The first (low pressure) sodium vapor lamp was introduced in early 1930s and while it had its advantages over other existing lighting sources, such as high efficacy, there were also some problems with these lights, such as lower brightness and very narrow light spectrum, producing an intense yellow color which made them pretty much useless for indoor and outdoor lighting where color rendering is very important.

When the first low pressure sodium lamp was introduced, it was known that by increasing the pressure inside the arc tube, a bulb with improved energy efficiency and color rendering could be achieved. However, non of the materials present at that time used in bulbs couldn’t resist the high pressure and heat inside the tube, so in 1955 a material called Lucalox (aluminum oxide ceramic) was invented by General Electric. Few years after this invention the first practical high pressure sodium vapor lamp was introduced by GE.

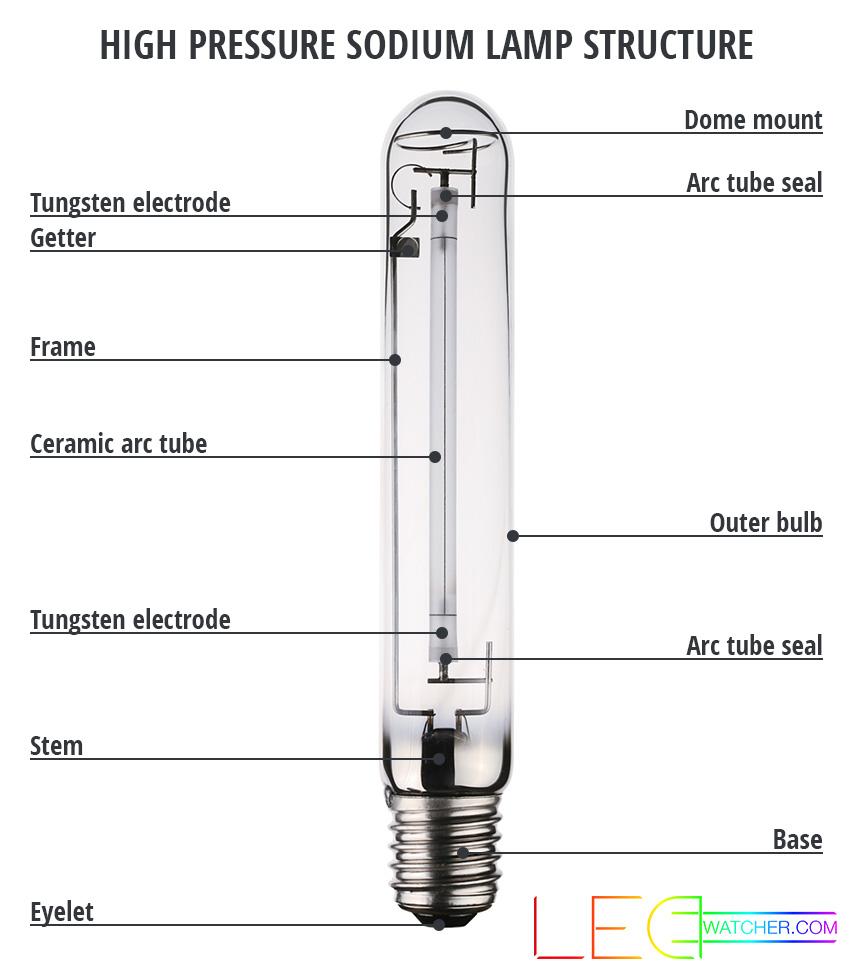

High pressure sodium lamps differ from other types of high intensity discharge lamps as they contain a mixture of xenon and sodium-mercury amalgam, which gives the lamp its orangish glow. The arc tube is made from a translucent ceramic material that can withstand high chemical activity and extremely high temperatures up to thousand degrees celsius (over 2000 degrees fahrenheit).

Xenon is used as the starter gas until it warms up the arc tube for mercury to vaporize, and while it vaporizes, the temperature inside the tube continues to build until the sodium starts to vaporize too, shifting the color of the lamp to more orangish. The color of different HPS lamps can vary depending on the brand of the bulb.

Because of such advantages as high efficacy and relatively long life span, these lamps are used in variety of applications, such as:

- Street and road lighting – Probably the most common use of high pressure sodium lamps from their early days are as a street and road lighting. Although HPS street lights are extensively being replaced with the newer LED lamps that bring numerous of advantages and are much more future proof lighting, there are still many cities across the world where HPS lamps are used as the main lighting source for illuminating the streets.

- Security lighting – Thanks to the high energy efficiency of HPS, they are also being used as outdoor security lighting.

- Outdoor lighting for large areas – Besides street and road lighting, high pressure sodium lamps are used in flood lights to illuminate other large outdoor and industrial areas.

- Plant grow lights – One of the most common uses of HPS lamps is for plant growing. HPS have been one of the first lamps used for indoor plant growing and are still widely used as plant grow lights, thanks of their high efficiency and their specific, yellowish color, which is great for plant flowering state, because it simulates the color spectrum a plant gets at autumn months.

- Interior lighting – High pressure sodium lamps are also being used as interior lighting in applications, where color rendering is not important.

HPS lamp specifications

- Efficacy – About 80 – 150 lumens per watt for standard high pressure sodium lamps, 30 – 80 lumens per watt for deluxe and white lamps.

- CRI – 20 – 30 for standard HPS lamps, 60 – 85 for deluxe and white lamps.

- Color Temperature – Around 2000K for standard HPS lamps, around 2700K for white lamps.

- Life span – 10000 – 24000 hours for standard HPS lamps

- Available wattages – Usually range from 35 – 1000 watts

- Restart time – Restart time for hot HPS lamp on average is 1 – 2 minutes, but for applications where continuous lighting is needed, special standby lamps are used that can maintain two arc tubes, allowing the lamp to restrike instantly.

- Luminous maintenance – Luminous maintenance of a high pressure sodium lamp depends on design and wattage of the lamp. High wattage lamps with 600 and more watts will loose about 20% of their initial light level at the end for their life, while lamps with lower wattage will loose only about 10% of their initial light level.

How do high pressure sodium lamps work

High pressure sodium vapor lamp consists from a compact arc tube surrounded by a glass bulb to protect the inner parts, keep temperature inside the lamp and filter UV radiation. The HPS lamp, similar to other high intensity discharge lamps, requires a ballast to operate.

The arc tube is made from aluminum oxide ceramic and has got a high pressure inside for higher efficiency. Inside the arc tube there is a mixture of xenon gas and sodium-mercury amalgam. On both ends of the arc tube two electrodes are located made from tungsten.

High pressure sodium lamps usually are started using an ignitor that sends pulses with high voltage through the arc tube using an external electronic circuit that is built into the ballast of the lamp.

Here are the steps how a high pressure sodium lamp starts:

- When voltage is applied between electrodes the arc is established through the xenon gas first. Xenon is a great starter gas because it has low thermal conductivity so there are very low thermal losses and it ionizes easily which allows to quickly start the lamp. At this stage, the color of the lamp is sky blue.

- The heat inside the arc keeps building up and mercury starts to vaporize. At this stage, the color of the lamp is bluish because of the blue tone of the mercury vapor.

- The mercury vapor continues to rise the temperature, pressure and operating voltage inside the arc tube until the conditions inside the tube get suitable for sodium to vaporize. The sodium is the last material to vaporize, emitting its pure yellow color which combines with the blue color of mercury and produces orangish color we are used to see from high pressure sodium lamps.Both colors together – yellow from sodium and blue from mercury, improves the color spectrum of the lamp and make objects under these lights easier to distinguish than, for example, under low pressure sodium lamps.

Advantages of HPS lamps

- High efficiency – HPS lamps have a very high luminous efficacy, producing about 80-150 lumens per watt, which is higher than any other type of high intensity discharge light. Only low pressure sodium lamps have higher luminous efficacy than HPS lamps.

- Long life span – High pressure sodium lamps provide a long service life, reaching up to 24000 hours and even more for some type of bulbs. HPS lamps have longer life span than LPS and MH lamps.

- Compact size – High pressure sodium lamps have a pretty compact size allowing them to fit into different types of fixture. HPS lamps are much smaller in size than low pressure sodium lamps.

- Reliability – Thanks to their long history of usage in various applications and mature technology, these lights are proven to be reliable in any situation.

- Good lumen maintenance – Depending on the design and wattage of the lamp, they will loose only 10 – 20% of their initial light level to the end of their life span.

- Improved color rendering of white and deluxe HPS lamps – Special white and deluxe lamps are designed for improved color rendering. While standard HPS lamps have CRI of 20 – 30, white and deluxe HPS lamps have CRI of 60 – 85, however these lamps are more expensive, have lower energy efficiency and shorter life span.

- Can be installed horizontally and vertically – HPS lamps can work both horizontally and vertically without any problems in operation.

Disadvantages of HPS lamps

- Low color rendering index – High pressure sodium lamps have low color rendering index of 20 -30, which means that it is more difficult to determine the true color of objects for a human eye under these lights. High pressure sodium lamps have worse color rendition than metal halide, fluorescent, halogen and LED lamps and some mercury vapor lamps, but better than low pressure sodium lamps that produce light in a monochromatic yellow color.There are special white and deluxe HPS lamps with much improved color rendering index of 60 – 85, however these bulbs lack other pros of standard HPS lamps such as great efficiency, life span and cheap price.

- Specific ballast requirements – The efficiency and life span of HPS lamps depend highly on the design of the ballast used. The ballast must correctly limit the voltage applied to the lamp.

- Not as efficient as LPS lamps – While HPS lamps have many advantages over LPS lamps which makes them a lot more commonly used, they still have lower energy efficiency than LPS lamps (luminous efficiency of LPS lamps can reach up to 190 lumens per watt).

- Can cycle towards the end of life – HPS lamps can cycle towards the end of their life, however, there are certain models that simply die at the end of life skipping the on and off cycling.

- Toxic mercury – Similar to other high intensity discharge and fluorescent lamps, metal halide bulbs contain small portions of the toxic element – mercury.

- Long warm-up and restart time – There is a warm-up time of approx. 15 – 20 min to start the lamp and also few minute restart time if the lamp has been running at an optimal temperature.

- Limited usage – Because of their poor color rendering and specific orangish color, usage of high pressure sodium lamps is limited to certain applications such as street lighting, factory lighting, grow lighting and special type of interior lighting.

HIGH INTENSITY DISCHARGE LAMP USAGE IN FLOOD LIGHTS

There are few characteristics that an outdoor flood light must meet:

- High light output;

- Low maintenance;

- Reliability;

- Efficiency;

- Durability.

One of the most important parts of a flood light is the bulb. What type of bulb is used in an outdoor flood light directly impacts practically all the criteria listed above – brightness, maintenance (life span of the bulb), reliability of lamp and luminous efficacy.

When it comes to flood lighting, there are 4 types of lamps mostly used depending on the application – LED, MH, HPS and Halogen (Mercury vapor lamps technically are used in flood light fixtures, however, they are a more outdated type of lamp with certain drawbacks, so other HID lamps and also LEDs have replaced them in most applications).

Although all 4 of these lamps are used as flood lights, the applications where they are used differ a lot. Here are the most common applications where each type of flood light is used:

- Halogen – mostly small backyard lighting around the house due their low efficiency and low initial costs.

- LED – in any type of flood light, starting from lower brightness indoor and outdoor lights used around the house or in backyard to powerful lamps used to light up parking lots, streets, industrial properties, arenas and stadiums.

- Metal halide – mostly to illuminate large outdoor areas such as parking lots, stadiums and similar, and also as high bay indoor lighting.

- High pressure sodium vapor – mostly as street and road lighting and also to illuminate other, large outdoor spaces where color rendering is not considered important.

So when it comes to powerful, outdoor flood lighting, there are basically three types of lights used – LED, Metal halide and high pressure sodium vapor.

As this article concentrates on high intensity discharge lights, we will leave LEDs off by now, although they are steadily replacing HID lights in many indoor and outdoor applications where flood lights are used.

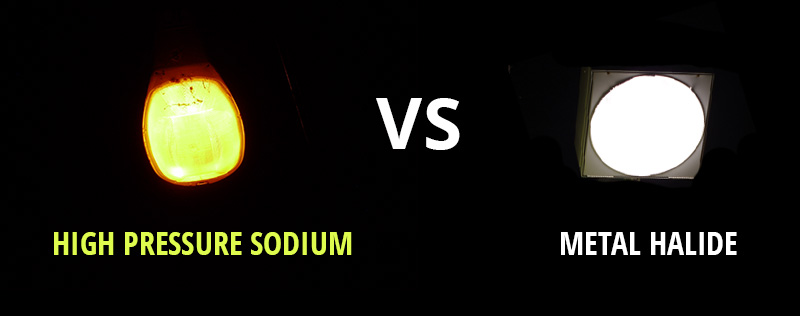

Metal halide VS High pressure sodium lamps. Which bulb is better for HID flood lights?

So in applications where high intensity discharge lamps are required, either metal halide or high pressure sodium lamps are the ones to choose from, because both of them have replaced older mercury vapor lamps due to their noticeable drawbacks such as lower energy efficiency.

When it comes down to which is better – MH or HPS lamps, it really depends on the application the lamp is going to be used, and because there are clear differences between both types of HID lamps, each of them are better suited for certain type of applications. So this isn’t also the case where one type of lamp fits in practically any application (LED?).

To compare both types of lamps, we will look at different aspects such as energy efficiency, longevity, color rendering and price, to determine which type of lamp is better at different applications where flood lighting is required.

Efficiency

Efficiency is important for any type of lighting, especially for high power outdoor flood lighting that consumes a lot of power and where energy efficient lamps can significantly reduce electricity costs.

When it comes to efficiency, high pressure sodium lamps are hard to beat. They are more energy efficient than metal halide and even LED lamps. If energy efficiency is your only concern, HPS lamps are your best choice for flood lighting.

Longevity and Reliability

Another important aspect to consider when purchasing a flood light is longevity, longer the life span of the bulb – less maintenance is going to be needed for the fixture.

While changing a lamp on smaller flood lights around the house may not be a problem, changing a lamp for stadium or street lighting that is located in more difficult to reach areas will usually not only take longer time, but also will cost a lot more.

The edge here goes again to HPS lamps, as they have longer life time, reaching up to 24000 hours, while metal halide lamps can only manage to last for about 10000 – 15000 hours. However, newer type of ceramic metal halide lamps have much improved energy efficiency and life span, meeting requirements of more applications where previously only HPS lamps were used.

Also high pressure sodium lamps are very reliable and you can expect them to run their rated life, while older metal halide lamps have higher chance to fail prematurely.

When it comes to reliability, another factor to consider is the color shifting problem of older metal halide lamps, where they shift in color during the end of their life time, while HPS lamps can keep the same color throughout their life time. Again, this problem has been fixed with the newer ceramic metal halide lamps that offer better color stability.

Color rendition

In many applications, this is the most important aspect to consider when purchasing a flood lighting. With a good color rendition it is much easier to recognise colors of objects, which is very important in retail applications, as well as for safety and security. A good color rendering index is considered 80 and above.

Metal halide lamps have very good color rendering index from 60 up to 95, making them suitable for a lot more applications than high pressure sodium lamps, which have one of the poorest color rendering indexes of around 20 – 30. This means that metal halide lamps are able to represent colors of objects more naturally, making it easier for a human eye to distinguish colors under these lights, while poor color rendition of HPS lamps makes objects look more yellowish.

Poor color rendition makes HPS lamps unusable in retail applications, where the buyer must clearly tell the color of the product. Correct color rendition is also important for security and safety, as it is easier for both humans and security systems to recognize the face and other characteristics of a burglar such as the color of its clothing or car in white light produced by metal halides rather than orange light produced by high pressure sodiums.

Also, people perceive white light to be brighter than it actually is, allowing to use less powerful lamps to reach the same effect as with lights that produce, for example, orangish color as HPS, this allows improving energy efficiency when using metal halide lamps.

Price

The last factor that many consider when purchasing flood lighting is their price. When choosing a high power flood light, other factors such as the design of the fixture as well as the durability and ingress protection makes up the largest part of the fixture’s price, and there is not that much of a difference which type of HID bulb you choose, as both MH and HPS lamps are priced very similarly.

Conclusion

Generally speaking, high pressure sodium lamps in most cases will cost you a bit less than similar brightness metal halide lamps. This is because HPS lamps have higher energy efficiency than metal halide lamps, which means that you can use a lower wattage bulb, which should also cost you less. However in reality, specifications as well as the build quality and the brand of the fixture will play a more important role to the pricing of the fixture rather than the type of HID lamp you will buy.

Excellent article! Thank you for taking the time to do such a great job! I learned much. Saving this one to file!

Arthur,

Excellent article sir. Stumbled on this article for photography purposes, got the answers I needed but kept reading all the details because of my commercial warehouse experience.

Thanks